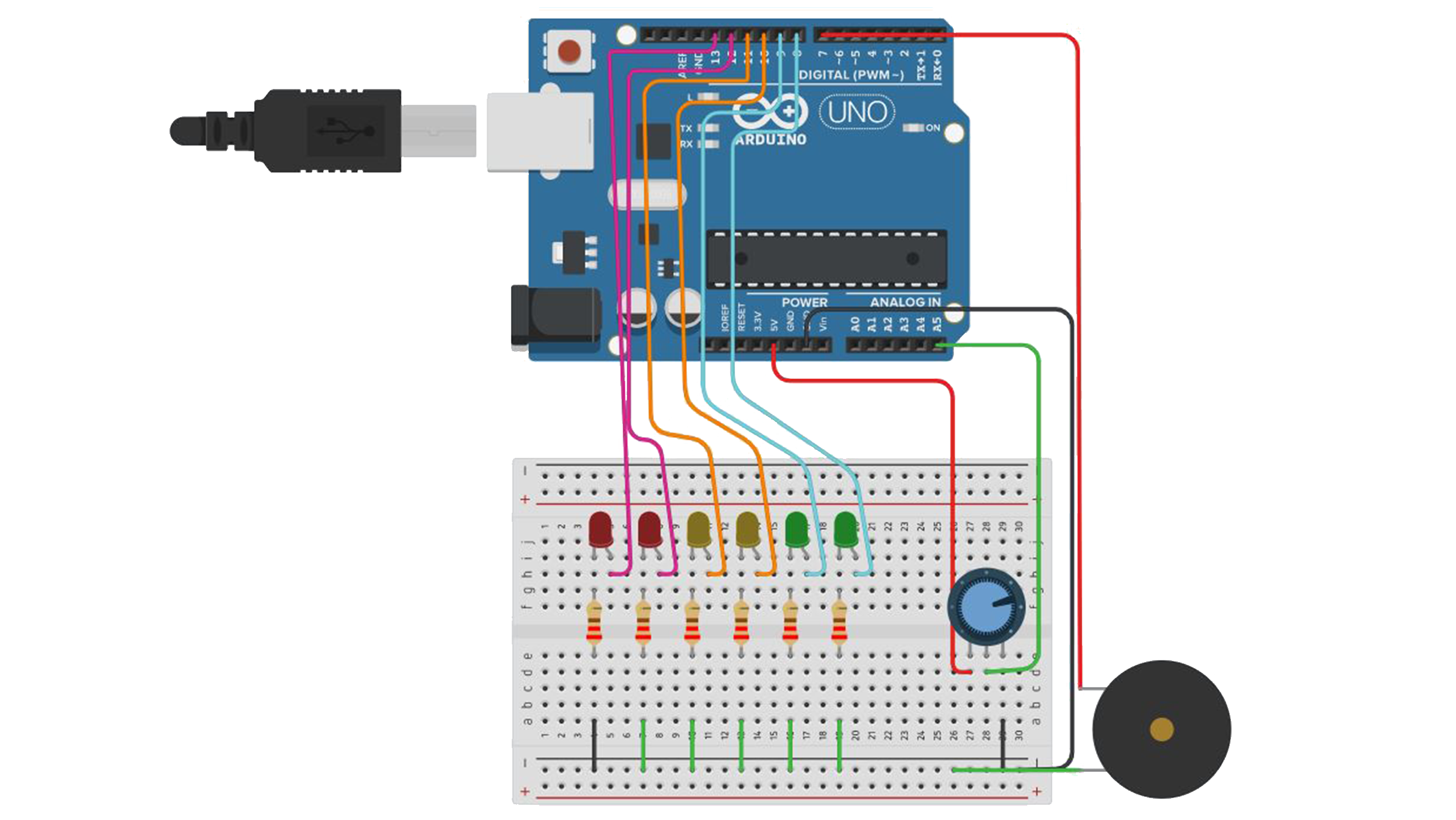

Project Description:

This project aimed to provide an understanding of how a product is assembled and manufactured, by physically disassembling (similar to the drill and blender) the product it provided visual evidence of the parts required to produce a 3D model of the product.

The shape of the body for this product has a variety of different curves, this influence of utilising a new method of 3D modelling. The method known as 'Surface Modelling' was briefly introduced and was achievable through the use of the 'Sketch Image tool in Solidworks. Sketching around the visual images and utilising multiple planes, it provided a more efficient process when needing to create a complex shape with a hollow inside.

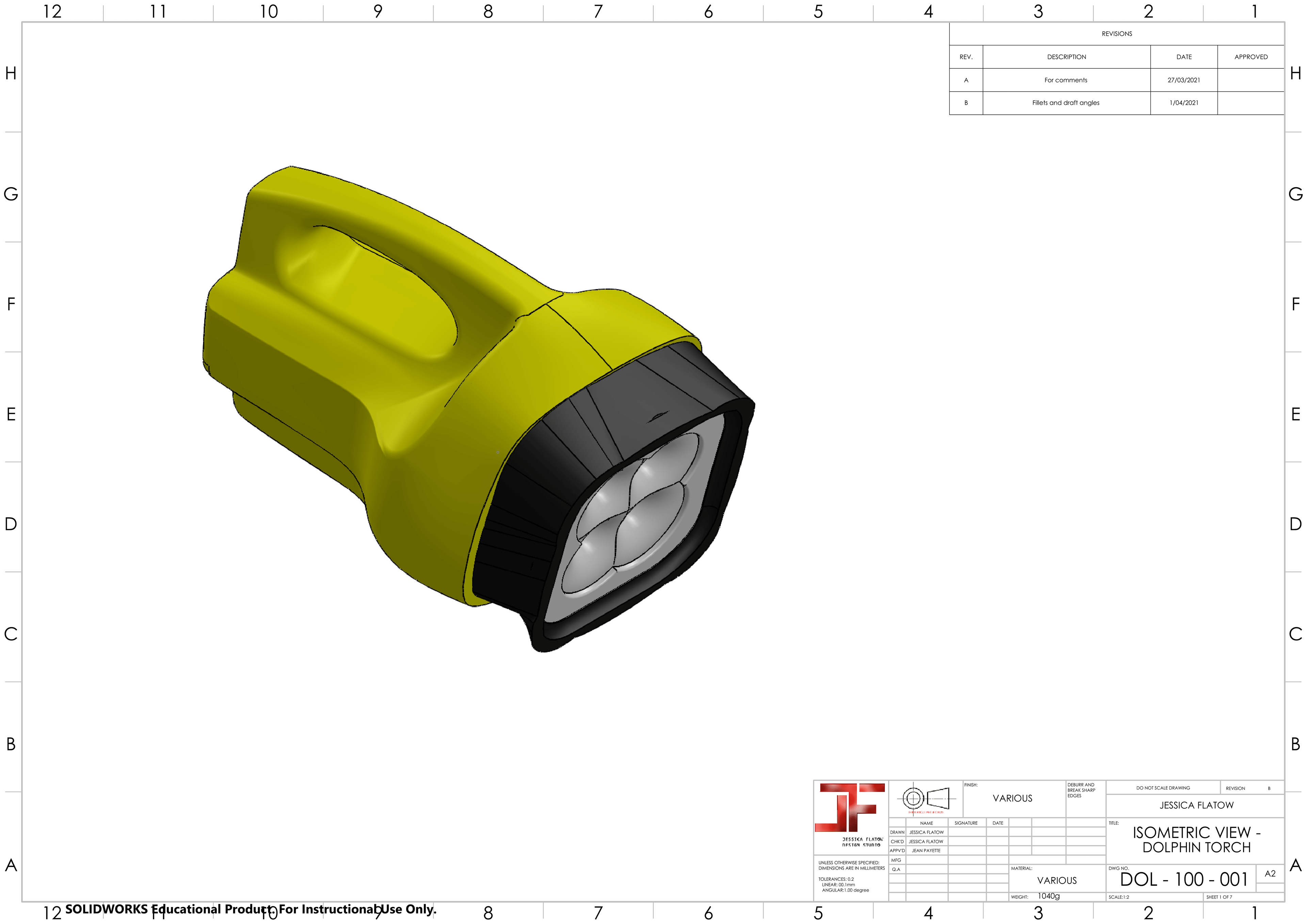

Dolphin Torch - Solidworks Rendering

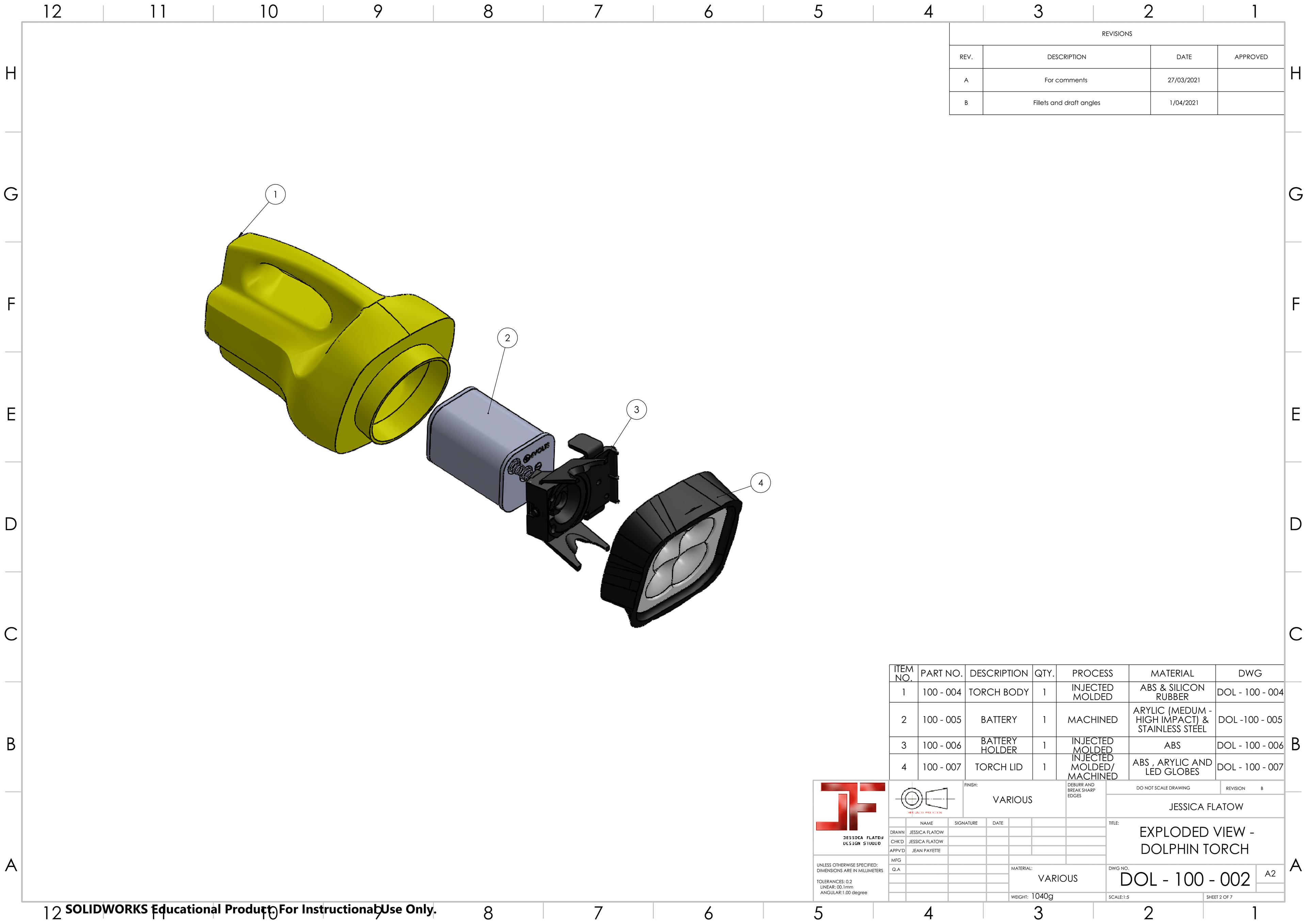

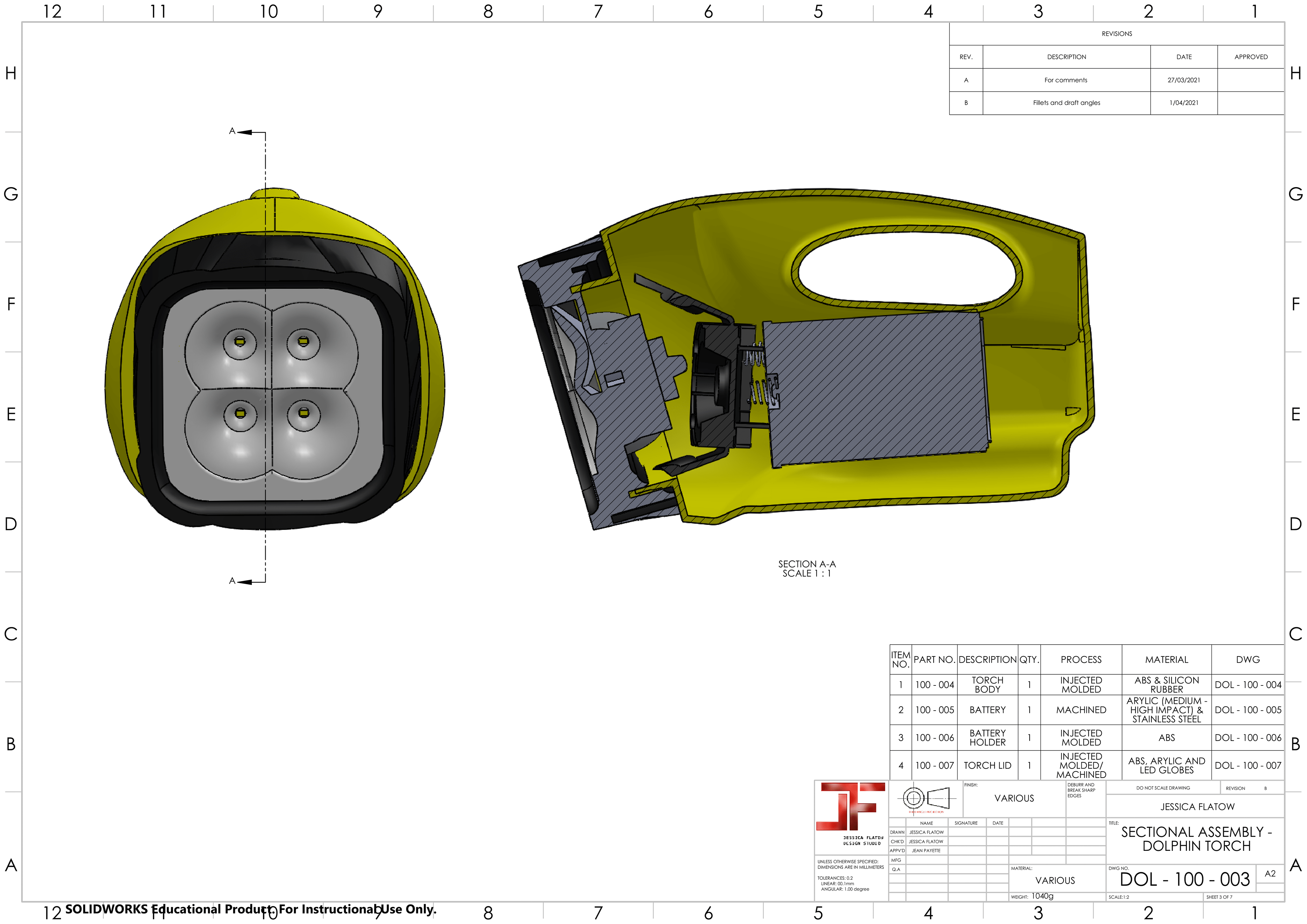

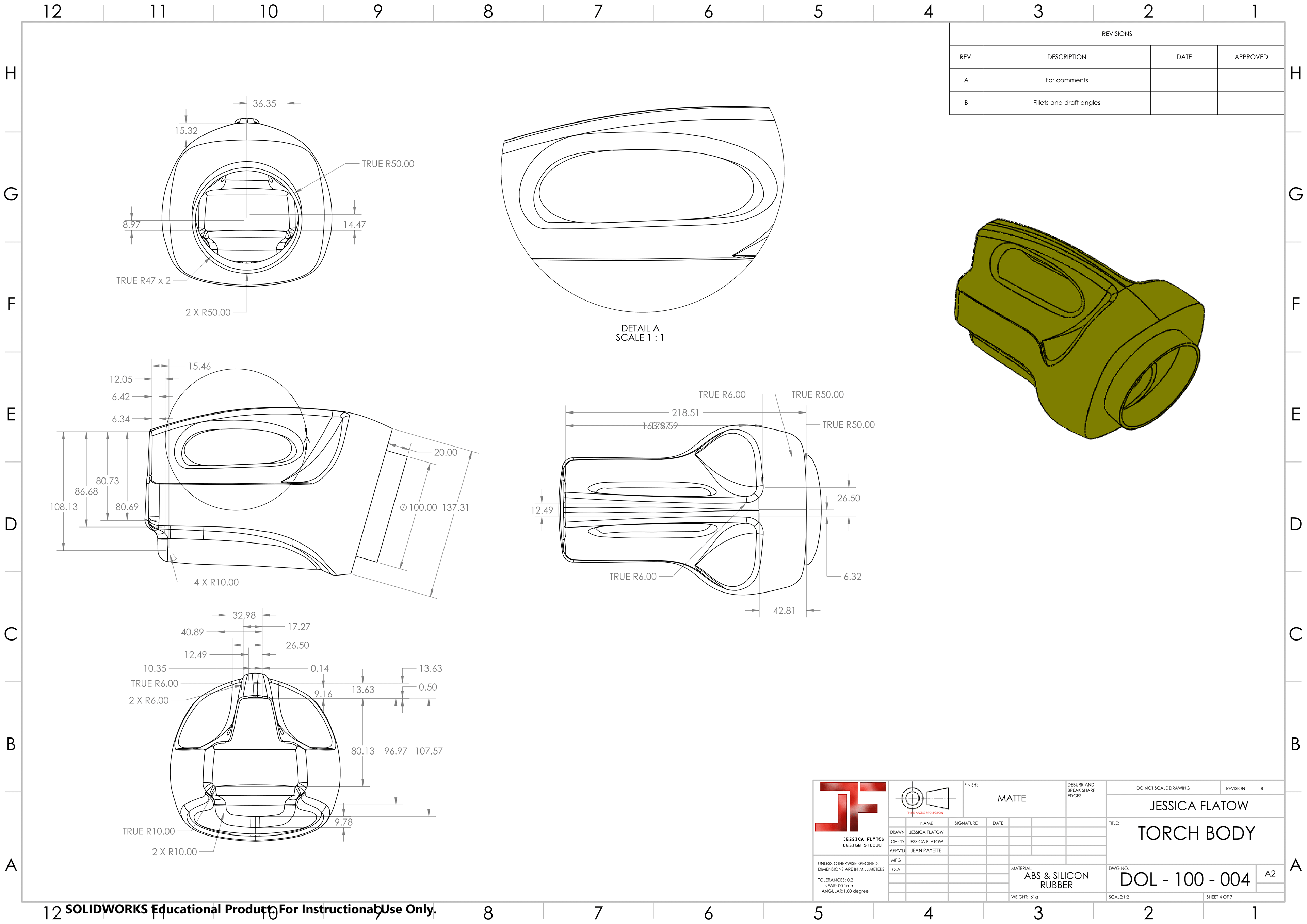

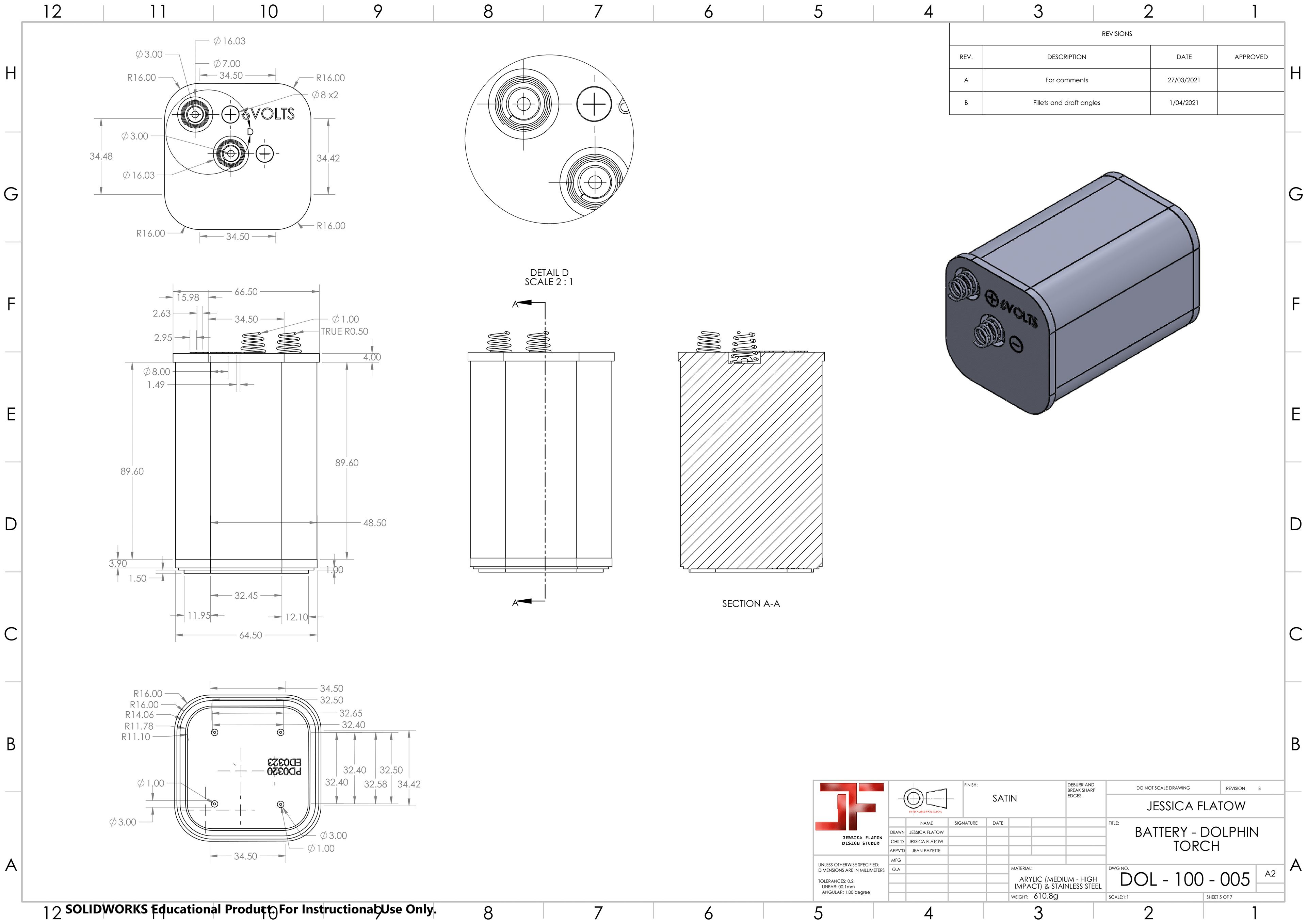

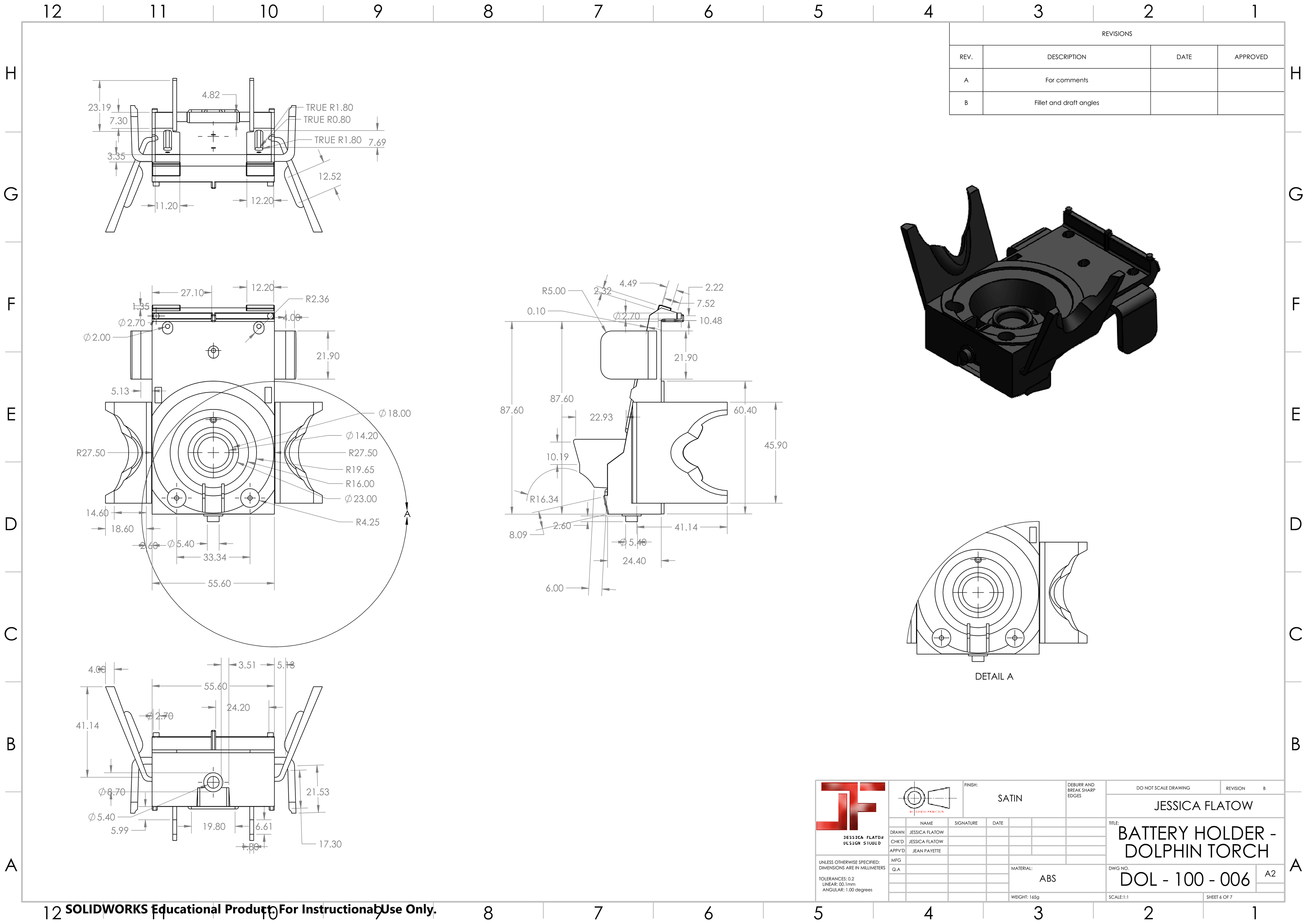

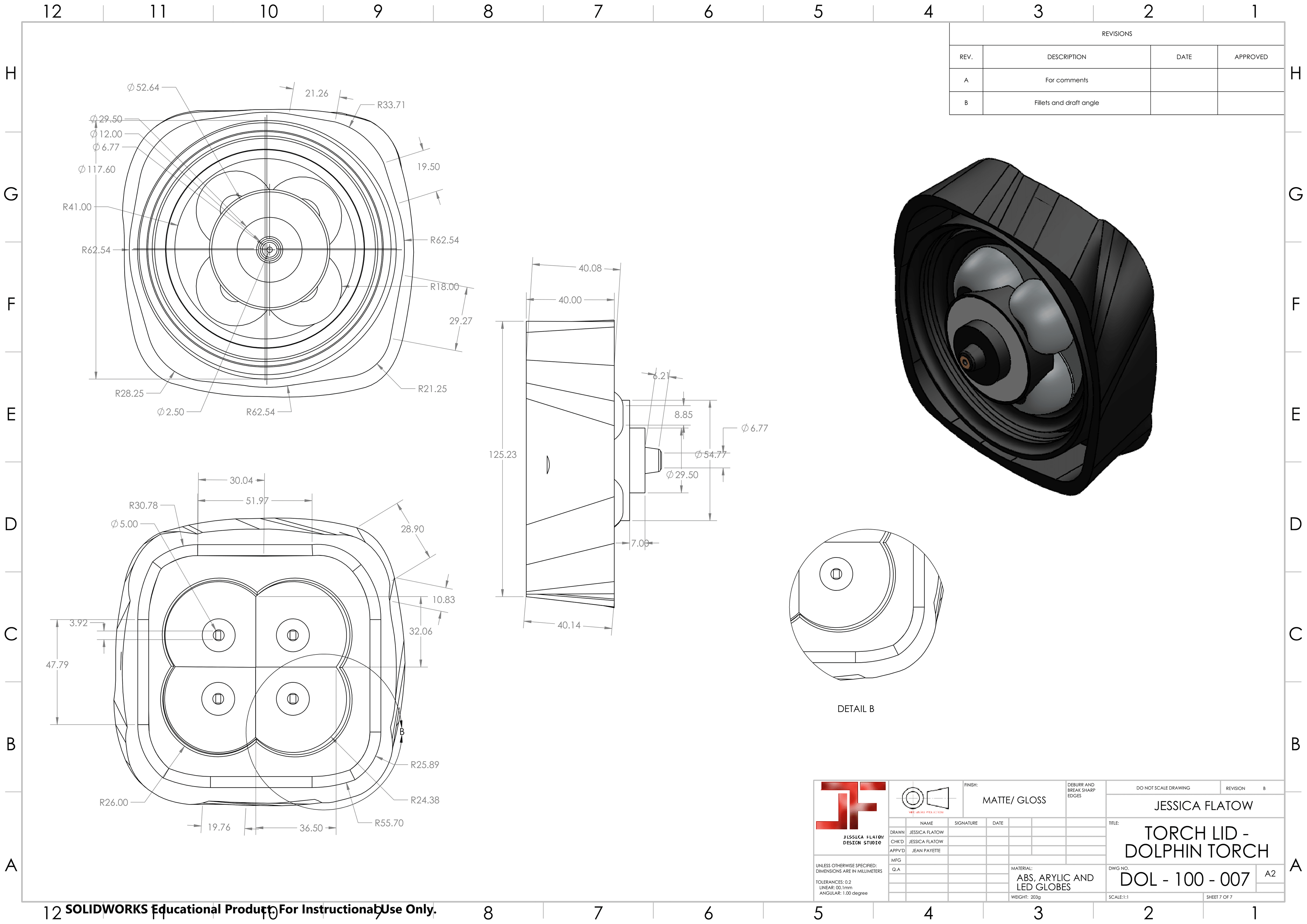

Engineering AS1100 Drawing Sheets:

Full Assembly

Exploded View

Sectional View

Torch Body

Battery

Battery Holder

Torch Lid

As discussed the aim of this project was to disassemble a product, then measure each part (utilising a digital calliper) and recreate each part on Solidworks, and then assemble the product back together. After recreating it on Solidworks through parts and assembly, it was then represented in Engineering A2 AS1100 Landscape Drawing Sheets. In this case, the product that was disassembled was a Dolphin Torch.

Above is an example of some of the drawing sheets that were produced for this assignment and overall, this project enhanced my learning towards using this Software (Solidworks); as well as learning how a product is manufactured and put together.